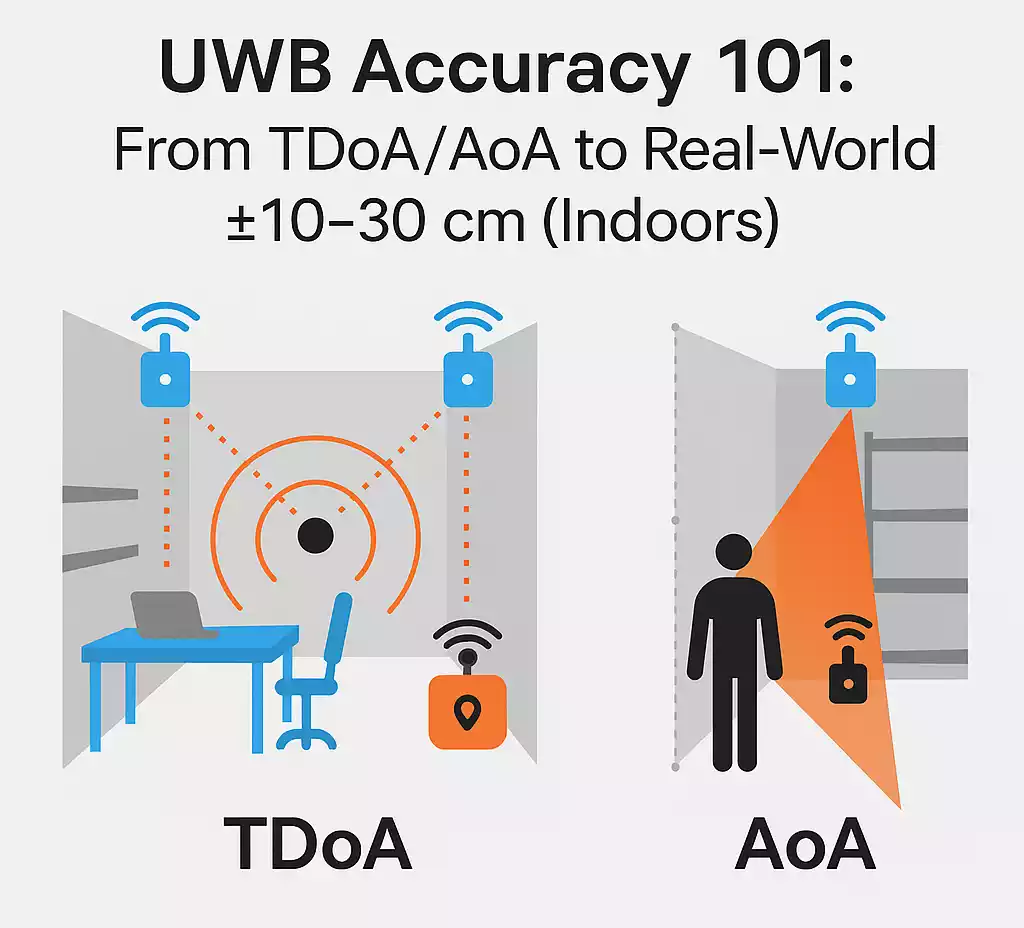

If you’re evaluating indoor real-time location systems (RTLS), one number keeps coming up: ±10–30 cm. That is the accuracy band top UWB indoor tracking systems routinely target on factory floors, warehouses, tunnels, and maintenance sheds. We explain what that number means, when to expect it, and how deployments reach it. This can happen through TDoA, AoA, or both. We also discuss what field results show in metal-heavy, reflective environments.

What “±10–30 cm” Really Means—and When You’ll See It

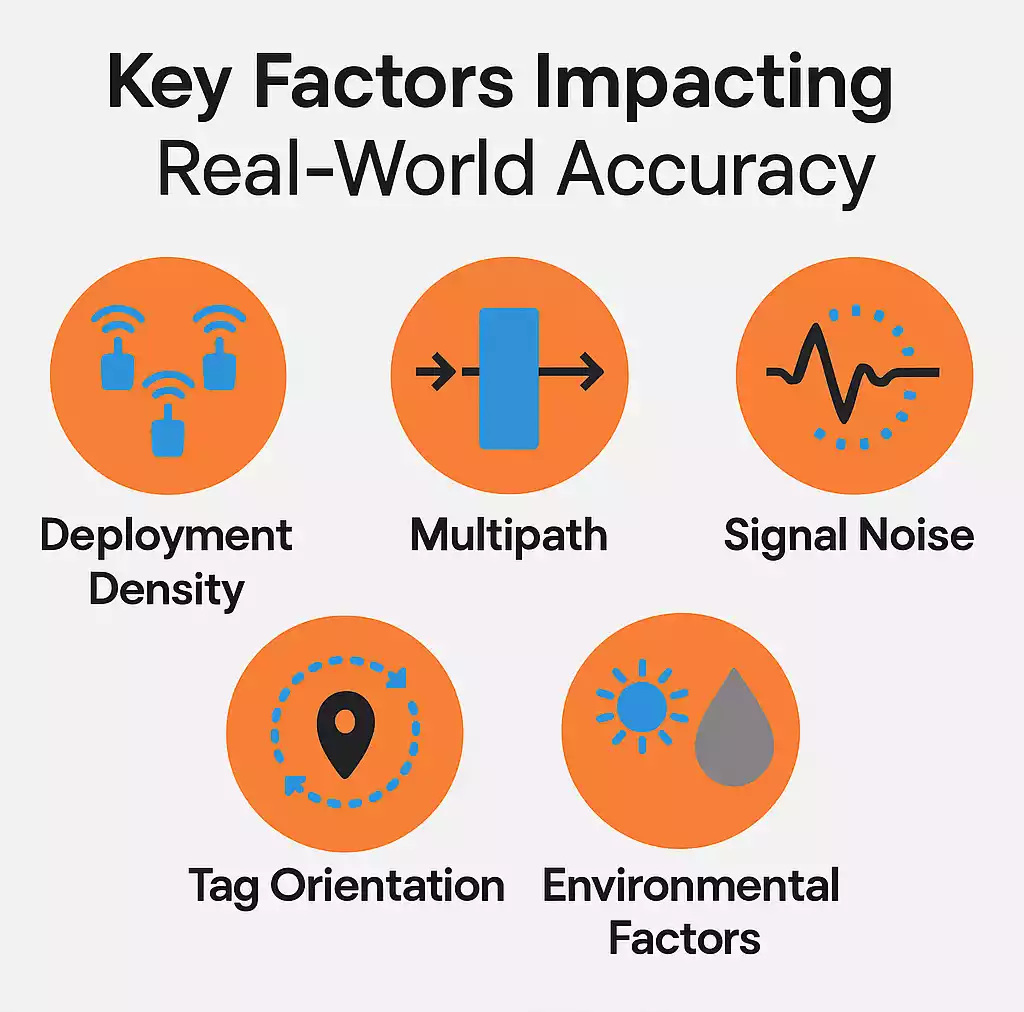

“±10–30 cm” shows the usual radial error of a tag’s position compared to its actual spot in a well-planned indoor UWB setup. It's not just a theory; it's what you can expect in real-world production. You’ll notice this when anchors are in sight, the environment is checked, and the system is calibrated.

Modern UWB RTLS platforms pair anchors, tags, a gateway, and software into one stack. These systems are designed for industrial use across many regions, floors, and cities. You can manage them from a central interface. You can use the same accuracy playbook at different sites. This means you won’t have to start over each time. It offers typical indoor accuracy of 10–30 cm. It also has tools like point-map calibration and smart diagnostics. These help speed up tuning.

A Few Practical Implications:

Precision Where It Matters

At cross-aisles, blind corners, workcells, and staging lanes, sub-foot accuracy helps trigger alerts and automations at the right distance—not too early or too late.

Consistent Multi-Site Standards

You can standardize acceptance tests and KPIs across your entire portfolio. This works for multiple floors and cities, not just pilot sites.

Battery Life isn’t A Blocker

Tags are built for long-lasting use. The spec sheet shows ultra-low power tags with lifetimes of months or even years, depending on the model and duty cycle. This means you won’t sacrifice accuracy for frequent charging.

TDoA vs AoA (and when to mix them)

There are two core ways UWB systems estimate indoor positions:

TDoA (Time-Difference-of-Arrival)

Multiple anchors detect when a tag’s short UWB pulse arrives. Small time differences turn into range differences. This helps trilaterate the tag’s position.

AoA (Angle-of-Arrival)

An array antenna measures the angle of the incoming signal. This helps you find directional bearings that can be triangulated.

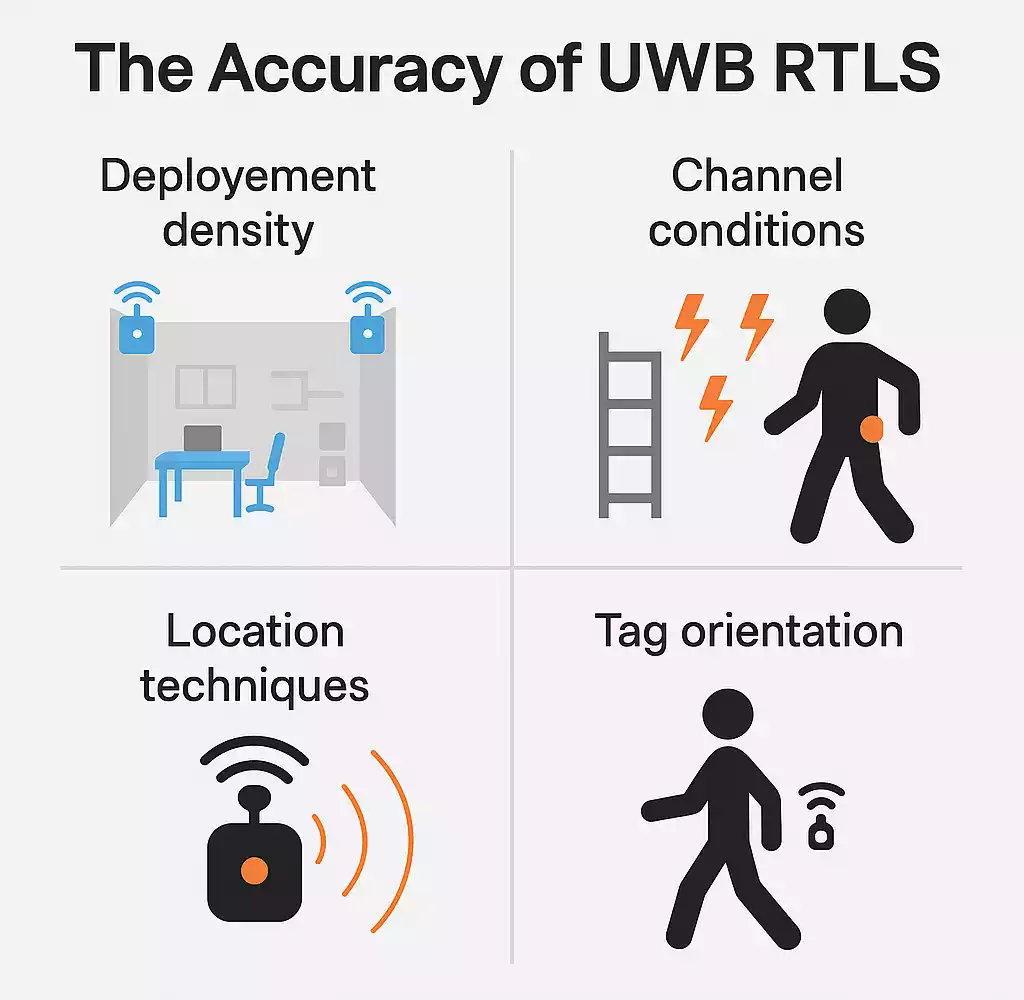

The IPS platform supports TDoA and AoA. It also allows mixed deployments. This helps you use fewer anchors while keeping accuracy, even when line-of-sight is not clear. A TDoA anchor indoors operates at UWB 6.5 and 8.0 GHz. It features an integrated omnidirectional antenna. At 6.5 GHz, it typically communicates over 100 m. The anchor uses ≤ 3 W via PoE and is IP66 rated. It works in temperatures from −40 to 75 °C.

The AoA indoor anchor features an integrated array antenna. It is IP68 rated and has a typical communication range of 20 m. This is helpful when angular discrimination is a key factor. There’s also an outdoor/complex-scene TDoA anchor (IP68) with external antenna, still PoE and ≤ 3 W, again cited at typical 100 m at 6.5 GHz. All anchors support cascade chains up to 6 to simplify wiring.

When to Mix (a practical rule of thumb):

Mostly Open Indoor Areas with Good Sightlines

Favor TDoA; it gives you coverage and accuracy with fewer anchors thanks to the longer typical communication range.

Clusters of Machinery, Reflective Bays, or Constrained Workcells

Add AoA in those pockets to stabilize geometry and reduce the number of extra TDoA anchors you’d otherwise need.

Outdoor Yards, Tunnel Portals, High-Humidity or Dust-Prone Zones

Select the IP68 outdoor TDoA model with an external antenna for durability. Keep your anchor density reasonable. Add AoA only when angles are essential.

Because all three anchor types share PoE, low power, and cascade capability, you get flexibility without wiring chaos.

The Accuracy Pipeline: Tag → Anchors → Gateway/API → Map (in real time)

Accuracy is not just a radio property; it’s a system property. The IPS architecture breaks it into a clear pipeline. The gateway transmits real-time data streams to an industrial IoT data platform that processes location updates, device status, and analytics dashboards in one unified interface:

Tags

(Badge, wristband, block, vehicle) broadcast compact UWB packets on a cadence you choose (e.g., 1 Hz in many duty cycles). Multiple form factors cover people, tools, vehicles, and powerable targets.

Anchors

Receive those packets, compute ranges (TDoA) and/or angles (AoA), and feed observations upstream over Ethernet/PoE.

Gateway

A Gateway aggregates observations and offers HTTP and WebSocket APIs (JSON). These APIs include device ID, status, location, and more. This real-time push allows the UI to update continuously, rather than polling on a timer.

Software

The Software layer enhances the operator experience. It provides real-time trajectory display and 2.5D map import. You also get electronic-fence alarms, camera tracking, heat-map generation, and organizational management. You can also playback historical data. These tools let you adjust zones. They also help you ensure that alert thresholds match your on-floor accuracy.

Two Additional Pipeline Notes that Influence Accuracy:

Planning By Range

For initial scoping, use the spec's typical 100 m communication range at 6.5 GHz (TDoA). This gives a good starting point for indoor zones. You’ll refine the anchor count and placement during surveys and walk-tests.

Cadence vs. Battery

Many customer deployments operate at 1 Hz for tracking people and vehicles. The tag sheet shows multi-month duty cycles at this rate. For example, a work card lasts 9 months at 1 Hz for 8 hours a day. A block tag powered by a CR2477 cell can last 18 months. This lets you hold update rates high enough for safety and flow without frequent swaps.

Field Results in Reflective Environments

Spec sheets are nice; field data closes the case. In a workshop with bright metal reflections and air partitions, partners measured 10 key points. They achieved an average accuracy of 0.221 m. The real-time diagnostic tools in the same deployment made anchor placement easier in tough conditions. After going live, personal injuries and material damage from non-standard forklift driving fell by at least 88%. This change saves around 300,000 CNY (about $40k) each year for every HVAC factory in compensation.

Other case patterns from the same stack:

Inventory and Tool Finding

In a large production setting, inventory time fell from 3 weeks to just 10 seconds. Single-device searches now take under 5 seconds, and errors dropped by 98%. This shows that the accuracy engine for safety alerts is also great for quick searches.

Steel Plants and Train Maintenance Depots

Sites with strong metal reflections and obstructions used indoor anchors and worker badges. This helped them position accurately. They set up electronic fences and built dashboards for supervision. This approach made maintenance leaner and safer.

Tunnels and High-humidity Construction

Outdoor complex-scene anchors (IP68) with helmet tags provided reliable personnel positioning. They also improved safety in areas where GPS doesn’t work.

Bottom line: The ±10–30 cm indoor claim holds true, even in metal-heavy, blocked areas. This accuracy directly impacts safety, search time, and costs.

How to Design for Accuracy from Day One

1) Start with The Right Anchor Mix

Begin with TDoA anchors for wide indoor coverage. Then, add AoA in areas with dense obstructions or where you need clear angles, like narrow bays. For yards, portals, and humid or dusty lines, use IP68 outdoor TDoA with external antennas. Keep PoE cabling simple using cascade chains up to 6.

Use Software to Validate Accuracy Continuously

Bring in your 2.5D map, draw electronic fences, and enable real-time trajectories so you can spot outliers. Historical playback and camera links help you answer questions fast. They also help you spot areas that need an extra anchor or an AoA assist.

2) Plan to The Spec, Tune to The Site

Use the typical 100 m comms figure at 6.5 GHz (TDoA) for rough planning. During the survey, check line-of-sight. Clear columns and place anchors so that two or more have a strong geometry across your target zone. Walk-test each hot spot before calling it done.

5) Lock in Acceptance Tests

For each zone, measure distance-to-alert, positional error across marked points, and repeatability across shifts. Standardize tests across all your facilities. Then, record the results in a central dashboard. The platform supports multi-floor and city-wide positioning.

3) Set Tag Cadences for The Job

People and forklifts often run ~1 Hz; carts/tools can be slower. The published multi-month battery figures at 1 Hz give you room to be generous without killing batteries.

These deployments show how precise results can be when hardware and analytics work together. This method was pioneered by the Affirmo Tech team in their ongoing RTLS innovations.

FAQ's

Contact Us

6 Ubi Road 1 #05-01

Wintech Centre

Singapore 408726