In busy warehouses and on production floors, a blind corner can cause a near-miss. This can lead to downtime, damage, and extra paperwork. Ultra-wideband (UWB) real-time location solves a key issue. Now, you can see where forklifts and people are at any moment. This helps you trigger alerts at the right distance. That precision is why UWB proximity systems have become a go-to for safety and efficiency on metal-heavy floors.

Below is a practical, customer-friendly guide to how it works, what to expect, and how to roll it out quickly.

Why Proximity Needs Centimeter-Level Accuracy on Metal-Heavy Floors

Traditional “zone” systems tend to be coarse. If your alert fires 2–3 meters late (or early), drivers either ignore it—or they still get surprised at a cross-aisle. UWB’s value is that it brings indoor location into the ±10–30 cm band that makes proximity alerts truly meaningful. Tightening a safety threshold from meters to centimeters helps everyone. Drivers slow down before corners. Pedestrians receive timely cues. Managers enjoy fewer “heart-stopping” radio calls.

UWB works well in industrial spaces. It handles steel racking, columns, partitions, and reflective surfaces. These elements often confuse other radio technologies. Mixing TDoA (time-difference-of-arrival) and AoA (angle-of-arrival) anchors helps you achieve accuracy. This approach uses fewer devices and improves reliability.

What This Means for Your Floor

Right-time alerts at blind corners and cross-aisles.

Fewer false alarms and less “alarm fatigue.”

Smoother traffic flow, with drivers and walkers trusting the cues.

How It Works?

A UWB forklift safety setup has four parts: tags, anchors, a gateway, and software. The stack is simple for users—wear the badge, drive the forklift; the system does the rest.

1. Tag the Mover

Forklifts/AGVs

A compact vehicle or block tag mounts securely on the machine.

People

A badge (work card) or wristband is worn like a normal ID.

Assets

Use small block tags on carts, cages, or valuable tools. This way, everything appears on the live map.

These tags are made for industrial use. They have IP-rated enclosures. Some models include visual and vibration cues. They also feature an SOS function. Typical duty cycles at 1 Hz can easily provide battery life for several months. Some block tags may even last around 18 months with common usage patterns.

2. Anchor the Space

UWB anchors (think low-profile boxes) are fixed on walls or columns. Indoors, a TDoA anchor gives a typical communication range of ~100 m at 6.5 GHz, runs on PoE, draws ≤3 W, and is built to IP66 with an -40~75 °C temperature rating. Use AoA anchors where you need angular discrimination (typical indoor communication ~20 m). For outdoor yards and complex scenes, there are IP68 TDoA models. They come with external antennas, use PoE, and consume ≤3 W. You can cascade up to 6 units per chain for neat, cost-effective cabling.

3. Anchor the See & Act in Real Time

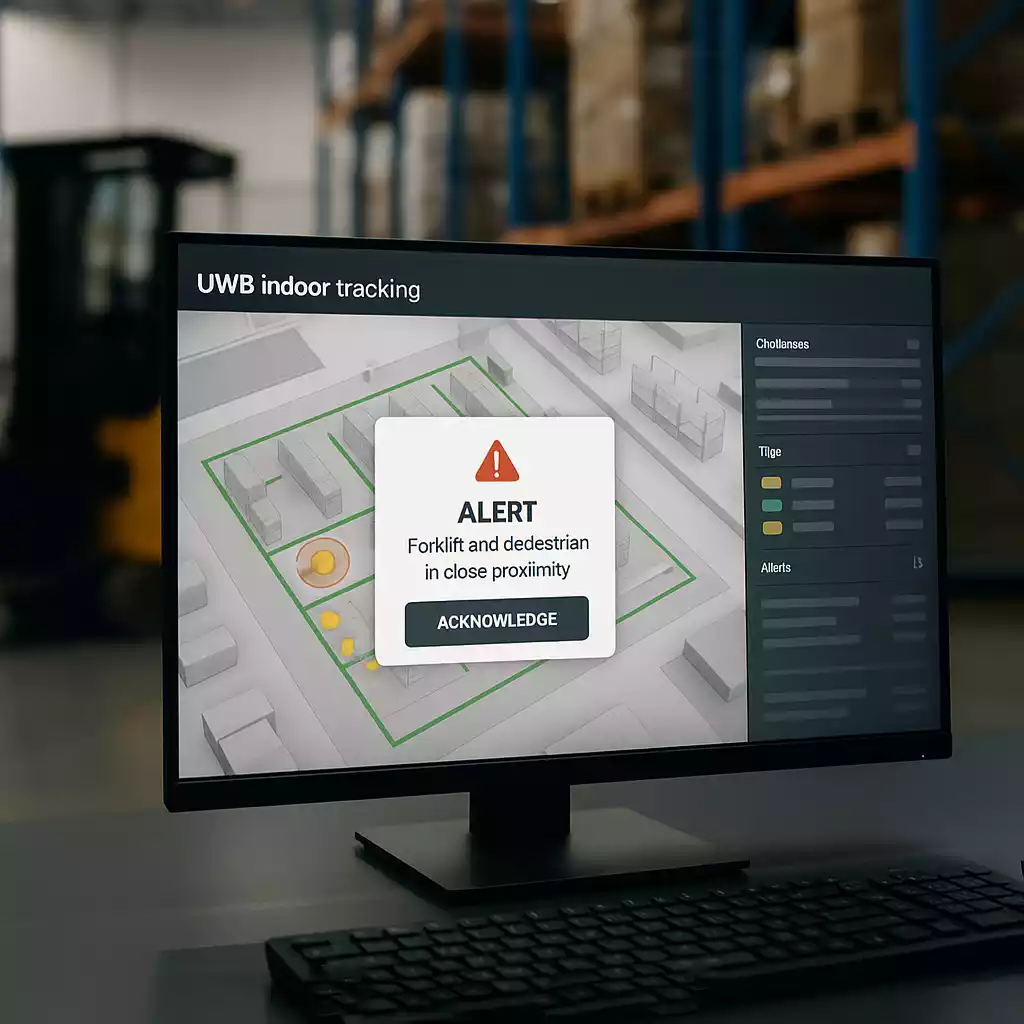

Position data goes to a gateway and into the software. It creates a live floor map with smart zones (geofences) and rules you set. You can set up alerts like a “slow-down prompt at corner X” or a “priority alert if a pedestrian enters the aisle while a forklift approaches.” You can also have a “restricted zone entry alarm.” For analytics, you’ll get heat maps, historical playback, and views to review shifts, hotspots, and compliance. You can also link alerts to cameras for instant visual verification and coaching after events.

What your team sees: fewer radio calls like “Anyone near Door 5?”; quick, helpful cues; and fast reviews for moments that felt “too close.”

What to Expect: Real-world Accuracy and Outcomes

Industrial environments are tricky—metal, humidity, sightline breaks. Field results show that UWB indoor tracking works well on metal-heavy floors. It reduces false alarms and speeds up driver response times. UWB proximity has proven it can handle those conditions and still deliver safety wins:

-

- In a real HVAC workshop with heavy reflections and columns, a deployment measured average accuracy of 0.221 m across ten key points. The system's smart diagnosis speeds up anchor placement and calibration. This happens even in tough conditions.

- After go-live, personal injuries and damage from non-standard forklift driving dropped by at least 88%. This saved around 300,000 CNY (about $40,000) per factory each year in work-injury compensation.

Those are conservative metrics to anchor your business case. When alerts fire early and consistently—and investigations are faster—costs come down and morale goes up.

Where It Helps Most?

Blind Corners & Cross-aisles

The classic near-miss. Create a geofence that starts a few meters before the sightline; give drivers a soft prompt (dash pop-up, light, or vibration). If a badge enters the crossing at the same time, escalate to a priority alert.

Dock Doors & Staging Lanes

Prevent surprise entries and over-speed approaches. If a forklift is approaching the threshold while a pedestrian enters, trigger a hard alert and log the event for coaching.

Pedestrian Walkways & Picking Zones

Racking hides people; UWB makes walkers “visible” to approaching traffic. Use soft prompts for painted walkways; escalate if distance drops below your safety standard.

Charging Stations & Maintenance Bays

Avoid crowding and reversing incidents by pacing entry. Simple rule: if two forklifts enter within n seconds, prompt the second to hold.

(Tunnels, steel plants, and maintenance sheds have done well with UWB tracking and geofence alarms. This shows that metal-heavy, obstructed spaces don’t pose a problem.)

Go-Live Fast: The 6-Step Playbook

Walk the Floor (60–90 minutes)

-

Mark 3–5 hot zones (corners, doors, cross-aisles, busy pick lines).

-

Note peak hours, known pinch points, and existing camera coverage.

Install & Calibrate (1–2 days)

-

Mount anchors; cable via PoE; verify network.

-

Pair tags to IDs/names in the dashboard.

-

Walk-test each zone to confirm alert distances and tune thresholds.

Define Simple Rules (30 minutes)

-

Choose one soft cue (speed prompt) and one priority alert (too-close) per zone.

-

Set a night-shift profile if you run different speeds or staffing after hours.

Train Quickly (1 hour total)

-

Operators & walkers (30 min): what prompts look/sound like; how to respond.

-

Supervisors (30 min): acknowledging alerts, checking playback, logging wins.

Select Devices (30–45 minutes)

-

People: badges/wristbands for those who traverse pilot zones.

-

Vehicles: tag forklifts on the affected routes; add AGVs if present.

-

Anchors: Plan coverage for each zone using PoE anchors. Indoors, budget for about 100 m typical comms range at 6.5 GHz for TDoA anchors. Optimize during the site survey.

Go live & Iterate (First 2 weeks)

-

5-minute daily stand-up: “Were alerts timely? Any false positives? Any blind spots?”

-

End of week 2: lock rules, then add one more zone.

The hardware menu is simple:

-

-

Use indoor IP66 TDoA anchors for general areas.

-

Choose indoor IP68 AoA anchors when you need angular info.

-

For outdoor or complex scenes, pick IP68 TDoA anchors with external antennas for yards or ports.

-

All options support cascading up to 6 and draw ≤3 W via PoE.

Simple KPIs to Prove It’s Working

Near-miss Incidents (Weekly)

-

What: Priority proximity alerts in pilot zones.

-

Target: Down 50–80% by day 30.

Investigation Time Per Event

-

What: Minutes from alert to root-cause understanding.

-

How: Use historical playback and camera linkage to shortcut interviews.

-

Target: Down 60–90% (most events resolved in minutes).

Alert Response Time

-

What: Seconds from alert to speed reduction/stop.

-

Target: Down 30–60% after the first week of training.

Cost of Injuries/Damage (Quarterly)

-

What: Claims, repairs, scrappage, overtime.

-

Why it matters: Sites report over 88% fewer injuries and damage. They also save around $40,000 each year in work-injury compensation per factory.

FAQ's

Contact Us

6 Ubi Road 1 #05-01

Wintech Centre

Singapore 408726